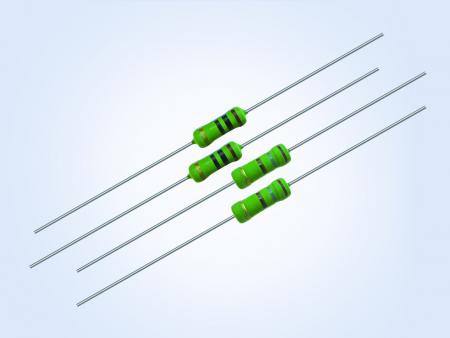

Wire Wound Resistor (1W 0.56ohm 2%)

WA01GR560TKZTB1K0

high power resistor, axial leaded resistor

Wire Wound Resistors 1W 0.56ohm 2% is designed by winding the metal wire around a ceramic core. In wire wound resistors, metal wire is used as the resistance element and ceramic core is used as the non-conductive material. We use Nichrome as the metal wires because they operate at high temperature and provide high resistance. The resistance of the wire wound resistor is depends on the resistivity of the metal wire, length of the metal wire, and cross-sectional area of the metal wire. Wire wound resistors are used in the electronic instruments where power dissipation are required.

| Size | Power Rating | Tolerance(%) | TCR(PPM) | Resistance(Ω) | Package |

|---|---|---|---|---|---|

| -- | 1W | 2% | -- | 0.56 | 1K/Tape Box |

Features

- Flameproof multi-layer coating equivalent to UL 94 V-0

- Color code per MIL & EIA standards

- Special tin-plated electrolytic copper lead wire

- Products meet RoHS requirements and do not contain substances of very high concern identified by European Chemicals Agency

Application

- Industrial Automation

- Measurement/Testing Equipment

- Power Supply

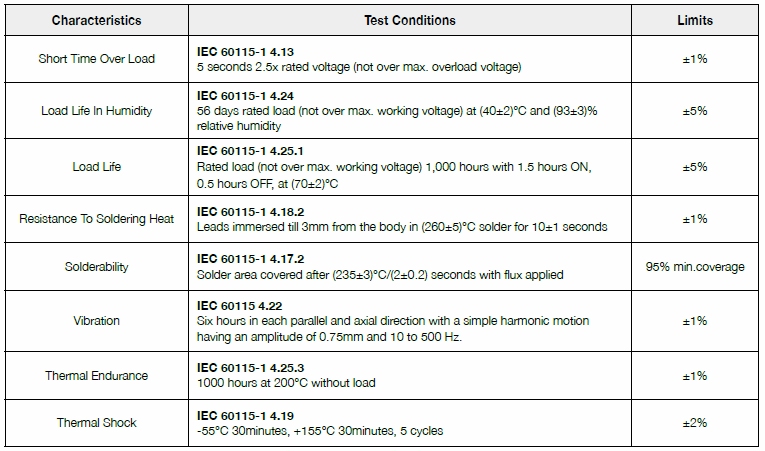

Performance Specification

Performance Specifications for wirewound Resistor, WA series

- Related Products

-

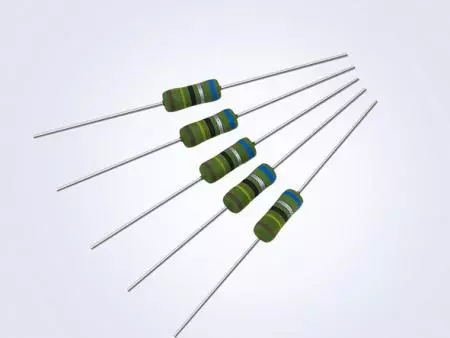

Anti-Surge Wire Wound Resistors-SWA

The Anti-Surge Wirewound Resistor (SWA series) offers a power rating from 1W to 6W, with a resistance range from 100m ohm to 1.2K ohm. The enhanced weld spot is not broken by surge impact, and the alloy wire can absorb harmful surge energy, making it suitable for high surge applications such as rush current protection of power capacitors, motor start-up protection, car & motorcycle engine ignition, thereby preventing the hazard of circuit damage caused by surge energy.

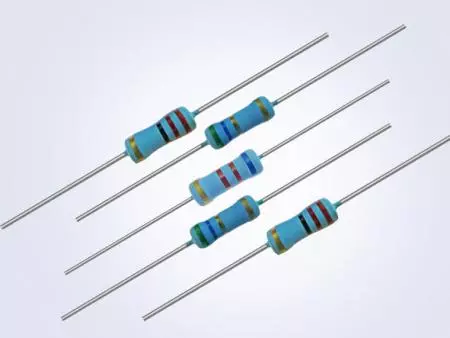

Metal Oxide Film Fixed Resistor-MO

Metal Oxide Film Fixed Resistor(MO) features a power rating from 0.5W to 7W and a resistance range from 0.1 ohm to 220K ohm. The standard tolerance is set at ±5% only, with a TCR of ±300PPM/℃. When compared with a metal film resistor, MO can support higher power requirements and withstand large pulse loads in high ambient temperatures while maintaining long-term stability. It is flameproof with multi-layer coating equivalent to UL 94 V-0 and is solvent resistant.

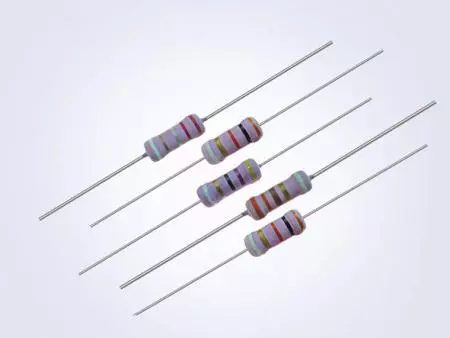

Pulse Safety Resistor-MSD

The Pulse safety Resistor(MSD series) features a power rating from 0.25W to 6W, with resistances ranging from 100m ohm to 1M ohm. It is made with the special composite film on a high-grade ceramic substrate, with flameproof multi-layer coating equivalent to UL 94 V-0. The resistor possesses excellent anti-surge capability and can absorb pulses from direct or inductive cross-coupling in the city power line, thereby protecting electric equipment or parts from accidental shock. Furthermore, an attractive point is its low-cost alternative to the wire wound resistor.

Anti-Surge Wire Wound MELF Resistors-SWM

The Anti-Surge Wire Wound MELF Resistor (SWM) features a power rating from 1W to 4W, with resistances ranging from 1 ohm to 3K ohm, and tolerance of ±1%, ±2%, and ±5%. The SWM series is applied in high surge applications such as high rush current protection for power capacitors, motor start-up protection, Electric Vehicle, renewable energy storage, etc., to absorb harmful surge energy, thereby preventing the hazard of circuit damage caused by surge energy. Due to its SMD-enabled structure with MELF style, it is better in heat dissipation than chip resistor, and it has a stronger mechanical structure to endure vibration and thermal shock.

- Download

Wire Wound Resistors

Wire Wound Resistor is designed by winding the metal wire around a ceramic core.

Download